The breathable stay in place concrete form that allows a full visual inspection of the pour and cure process.

Benefits

|

|

Centrally located and manufactured in St. Louis, MO to serve you better.

Most important – Made In U.S.A.

We offer a stronger, more economical, and versatile design in a wide range of widths and lengths to fit all your special fabrication requirements.

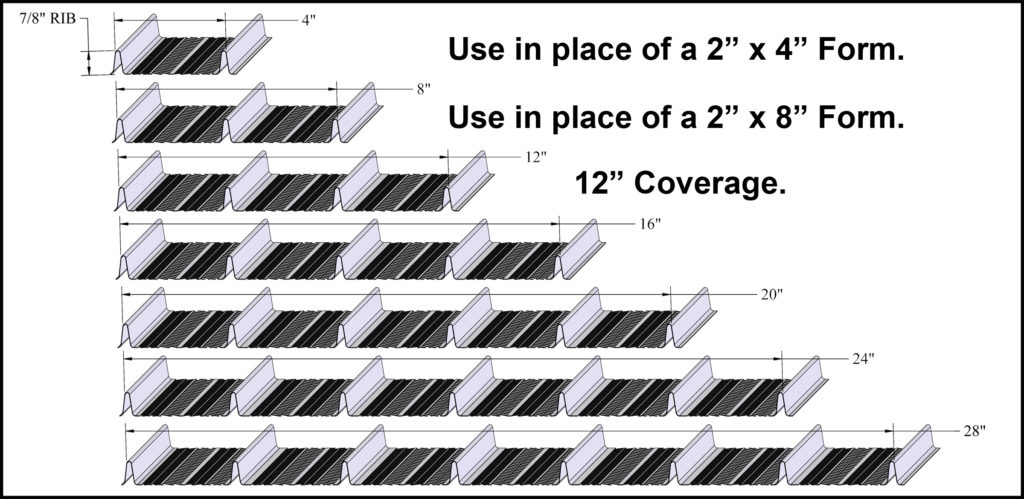

Special Widths: 4″, 8″, 12″, 16″, 20″, 24″, & 28″ Wide

Special Widths: 4″, 8″, 12″, 16″, 20″, 24″, & 28″ Wide

Special Lengths: 12″ to 240″ Long

Standard Sheet Size – 27-1/8” x 96″ ~ 18 Sq. Ft. ~ Approximate Weight 15 lbs.

| Standard Bundle Sizes | ||

| Sheets Per Bundle | Coverage | Approximate Weight |

| 5 | 90 Sq. Ft. | 75 Lbs. |

| 10 | 180 Sq. Ft. | 150 Lbs. |

| 25 | 450 Sq. Ft. | 375 Lbs. |

Concrete Form Usage

Expand-A-Form offers a taller stronger ribbed expanded metal leave in place concrete form for pour in place concrete. The recommended slump mix is approximately 3″ – 4″ but with proper precautions 6″ slump can be poured. This is depending on the ambient temperature, support spacing and bracing.

Use Expand-A-Form for forming bulkheads, pile caps, grade beams, blindside walls, construction joist, column and beam pockets, thrust blocks and anywhere it’s difficult to remove the forms. A smooth concrete finish would need back plastering. Expand-A-Form is excellent for below grade level forming or non-finished areas.

Concrete Form Installation

Expand-A-Form does not need special tools for installation. Sheets can be cut to length, notched, etc. using a circular saw with a metal cutting blade, tin snips, or small cutting torch. The end of a rebar can be punched through the expanded metal to construct bulkheads.

Erecting, using, and installing Expand-A-Form is like conventional plywood form panels, but they are lighter, easier, and faster to install. Place the panel ribs perpendicular to the supports with the rib spacing spanning between the studs or walers. The Expand-A-Form panel can be fastened to the supports with nails or wire tying with the ribs placed into the first pour.

Place the bottom panels first for vertical forms. Overlap and nest the panel ribs down the length of the panel and join to the support. The Panel ends should be overlap about 2″ to 3″ and join together at each rib.

Overlapped panel side joints should be wire tied every 12″ between supports. Fasten the Panels every 8″ along the supports. Overlapped panel end joints should be staggered between courses.

Brace the Panels against the concrete pour pressure as in all conventional form construction. Do not exceed bracing / pour rate guidelines. Stay at least 2″ to 3″ from the panels when the vibrator is required.

Material Specification

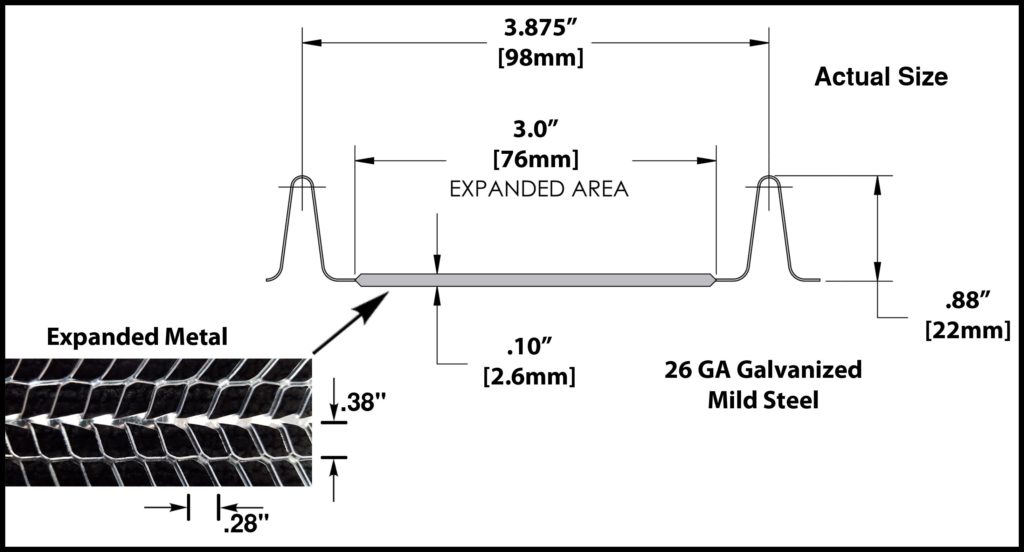

Thickness: 26 Ga. (.018) Type 66 Galvanized Mild Steel per ASTM A525-83 with physical and load bearing safety factor per C1-347.

Fabrication in accordance with ASTM C947 from Hot Dipped Galvanized Coil Strip meeting ASTM A653 / A653M.

Expand-A-Form is a coil fed process designed to lance the sheet and rollform eight (8) ribs down the length of the strip as it expands the lanced mesh areas between the ribs. Our ribs are deeper (.24mm) .88″ tall providing added panel strength. The ribs are spaced approximately 3-7/8″ apart. The material between the ribs produces an expanded mesh with a parallelogram opening size of 1/4″ x 3/8″.

Standard finished panels are 27″ wide and 97″ long. For special applications, we can make the panels in lengths of 12″ to 240″ long. We also offer panels in widths of 4″, 8″, 12″, 16″, 20″, 24″, and 28″ wide.